In commercial furniture sourcing, price comparison is often the first and most influential step. When multiple plastic chairs appear similar in design and function, the lowest unit price can seem like the most rational choice.

However, in cafés, restaurants, bars, hotels, and public spaces, the cheapest plastic chair frequently becomes the most expensive option over time. The reason lies not in the purchase price, but in everything that happens after the chairs are delivered.

Professional buyers evaluate products based on Total Cost of Ownership (TCO) rather than unit price alone. TCO reflects the full cost of a product throughout its service life, including replacement, logistics, maintenance, and after-sales handling.

For commercial chairs, TCO is driven by five key factors:

A low upfront price often hides higher downstream costs.

Low-cost plastic chairs are commonly designed for residential or light-duty use. When placed in commercial environments, they experience accelerated wear due to continuous use, frequent movement, and variable load conditions.

As a result:

Over multiple locations or large volumes, these repeated replacements quickly exceed the initial savings gained from a lower unit price.

Cheap chairs often generate a higher volume of customer complaints related to instability, cracking, or surface degradation. Each complaint creates indirect costs that are rarely included in sourcing decisions.

These costs include:

In commercial settings, complaint management can become a recurring operational expense rather than an exception.

Packaging and stacking design significantly affect landed cost. Low-priced chairs frequently use packaging that prioritizes simplicity over container efficiency or structural protection.

Poor logistics optimization leads to:

Even small inefficiencies multiplied across multiple shipments can outweigh unit price advantages.

Commercial chairs are moved, stacked, cleaned, and stored daily. Products not designed for this reality introduce ongoing maintenance issues.

Examples include:

Each failure disrupts operations and reduces usable seating capacity, particularly during peak hours.

At MAKA Furniture, commercial chairs are engineered to minimize total ownership cost rather than compete on lowest unit price.

Key design principles include:

By addressing durability, logistics, and consistency together, long-term cost is reduced even when the initial price is not the lowest.

In a multi-location food and beverage operation, replacing low-cost seating with chairs designed for commercial use resulted in measurable savings.

Over a two-year period:

Despite a higher initial unit price, the annual cost per chair was significantly lower.

To avoid hidden expenses, professional buyers should ask:

These questions shift sourcing decisions from short-term savings to long-term stability.

In commercial environments, plastic chairs are operational assets. Choosing solely based on unit price transfers risk downstream, where failures are far more expensive to resolve.

Evaluating durability, logistics efficiency, and real usage performance allows buyers to reduce total cost of ownership and protect long-term margins.

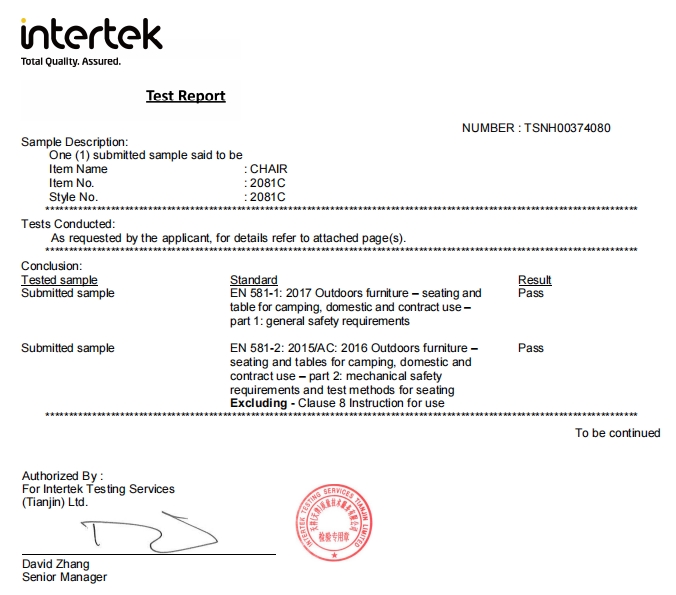

Founded in 2013, MAKA Furniture manufactures lightweight, durable, and space-efficient commercial furniture for indoor and outdoor use. With EU patents, EN12520/EN581 certifications, GRS eco-certification, and BSCI approval, MAKA supports global importers, distributors, and project buyers with seating solutions designed to reduce total procurement cost over time.

Fill out the contact form with your ideas today and find the right furniture sets for your room applications.