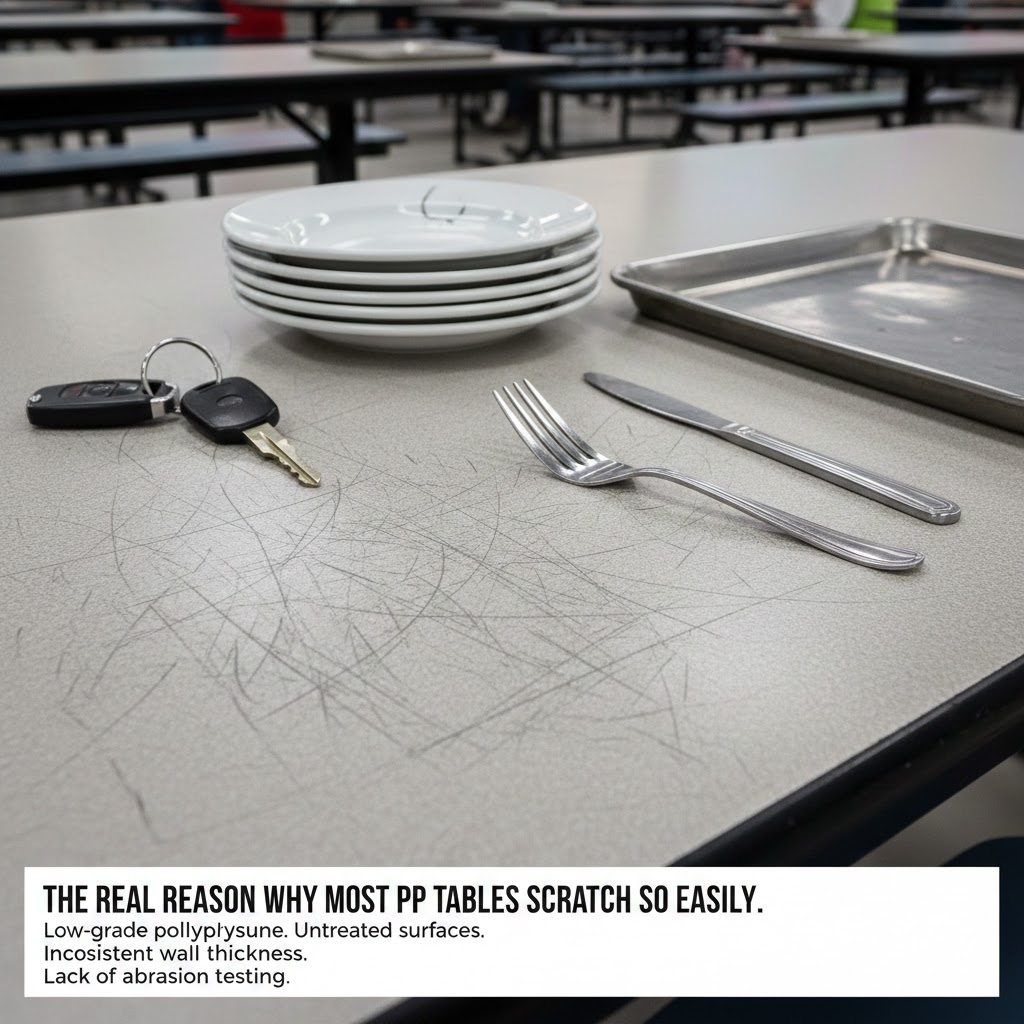

Plastic PP tables are widely used in cafés, restaurants, terraces, hotels, and commercial outdoor spaces because of their light weight, weather resistance, and cost efficiency. However, many buyers share the same frustration after a short period of use: visible scratches caused by keys, cutlery, plates, and daily friction.

Once these scratches appear, the table surface quickly looks old, cheap, and poorly maintained—even if the structure itself remains intact. For high-traffic commercial environments, this is more than a cosmetic issue; it directly affects brand image, customer perception, and replacement costs.

Not all PP tables are created equal. Scratching problems are usually caused by material shortcuts and surface treatment limitations, including:

In real commercial use, tables are constantly exposed to metal objects such as keys, forks, knives, trays, and stacked plates. Even normal cleaning and stacking can leave permanent marks on standard PP tabletops.

An abrasion-resistant PP table is not defined by appearance alone. It is the result of material engineering and surface design working together.

In our production, scratch resistance is achieved through a combination of:

Instead of a soft, glossy surface that highlights every mark, the tabletop is engineered to withstand daily friction without showing obvious damage.

For cafés, restaurants, hotels, and distributors, improved scratch resistance delivers tangible operational value:

This is especially critical for outdoor dining, high-turnover cafés, food courts, poolside areas, and event venues, where tables are constantly moved, stacked, and cleaned.

A commercial PP table should not be designed for light residential use—it must survive repeated daily abuse. That includes:

Our abrasion-resistant PP table surfaces are developed specifically for these conditions, ensuring that normal daily use does not translate into permanent surface damage.

While many PP tables look similar at first glance, the difference becomes obvious after months of use. Tables that resist scratching do not just last longer structurally—they retain their value visually, which matters in customer-facing environments.

For professional buyers, choosing an abrasion-resistant PP table is not about paying more upfront—it is about reducing total cost of ownership over the product’s lifecycle.

Scratches are not an unavoidable flaw of plastic tables—they are a result of design and material choices. By focusing on abrasion resistance from the beginning, it is possible to produce PP tables that withstand real commercial use without looking worn or damaged.

For businesses that care about durability, appearance, and long-term value, scratch-resistant PP tables are no longer optional—they are essential.

Fill out the contact form with your ideas today and find the right furniture sets for your room applications.