Many people have some questions and misunderstandings when buying plastic furniture. Such as “I have seen plastic furniture, like the plastic furniture of food stalls ” or “Is there any difference in plastic furniture?”, “Which material of plastic furniture is better?”, “Why are there many plastic furniture for food stalls is cheap, but some plastic furniture is relatively expensive?”

MAKA will introduce to you the difference between food stall furniture and plastic furniture.

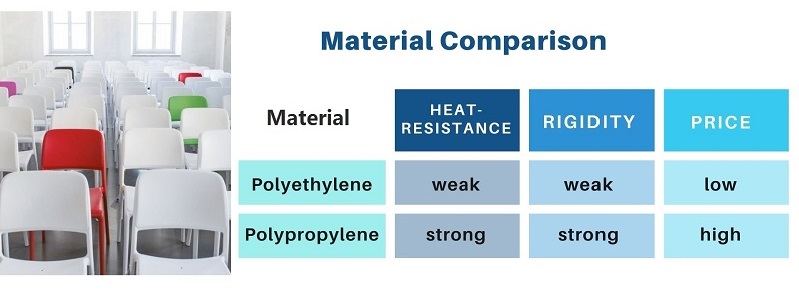

1. Material

First of all, let us first understand what is food stall furniture. Food stalls usually refer to the outdoor dining chairs industry. Imagine that in the hot summer, many people like to sit outdoors and eat while blowing the cool breeze, these outdoor dinings are generally called food stalls. The furniture used in these outdoor catering is what we usually call food stall furniture. Plastic furniture is a common choice for food stall furniture. Plastic furniture is widely used in food stalls because of its rainproof, moisture-proof, easy cleaning, easy stacking and storage, and low price. However, the materials of plastic furniture are also divided into many kinds, food stall furniture usually uses polyethylene, and another widely used plastic material is polypropylene for furniture industry.

Polypropylene

Polypropylene is referred to as PP. A colorless, odorless, non-toxic, translucent thermoplastic lightweight general-purpose plastic, which with chemical resistance, heat resistance, electrical insulation, high-strength mechanical properties and good high abrasion-resistant processing performance, this has made polypropylene rapidly widely used in many fields, such as machinery and furniture since its inception.

Polyethylene

Polyethylene is referred to as PE. It is a thermoplastic resin made by polymerization of ethylene. Odorless, non-toxic, feels like wax, has excellent low-temperature resistance, good chemical stability. It is mainly used for pipes, packaging materials, ropes, wires and cables in daily life.

2. Rigidity and Elongation

Polypropylene and polyethylene have different performance characteristics. Rigidity and stretch, these two points are important concerns in the furniture industry. Take a chair as an example, the most important thing about a chair is the load-bearing capacity of the chair. If the load-bearing capacity is not up to the standard, a funny scene will happen. Maybe you sit well but fall down suddenly, this is not a joke, it will happen and it will also cause harm to your body. Hardness and elongation are often related to each other, so it is not enough to just look at the hardness. Only chairs with hardness but not good elongation will be easily damaged when impacted by external forces and resulting in short service life.

Polypropylene

The main characteristics of polypropylene are low density, high rigidity, and high support. It is the preferred furniture material for bearing and extrusion. For example, the most common furniture, a chair, which is to bear the weight of the human body, and the pressure is facing downward, this way of receiving force is the specialty of polypropylene. This is why plastic chairs and plastic square stools must be made of polypropylene, because the chairs and stools are to support the weight. At the same time, because polypropylene has high tensile strength and good bending resistance.

Polyethylene

Polyethylene is characterized by high flexibility, bendable and can contain everything. This material is usually used for daily life items, such as plastic buckets and plastic baskets. This product is used to wrap things. For example, the weight of your bucket of water, for the bucket, its force is wrapping. The force is omni directional and requires toughness to contain it, so most plastic buckets and baskets use polyethylene.

3. Heat resistance

Heat resistance is a point that the furniture industry has to mention, and it is also a very important point, especially for outdoor furniture. The hot summer is a hot season for outdoor furniture. It is understandable that in the hot summer, people usually choose to gather with their families to enjoy leisure time on weekends in the courtyard of their homes. The fresh air and breeze outdoors can relieve the pressure of life. Summer is the hot season for outdoor furniture, and heat resistance has become a point that many customers and retailers value.

Polypropylene

From the perspective of heat resistance, the melting temperature of polypropylene is about 40%-50% higher than that of polyethylene, which is about 160-170℃, so the product can be sterilized at a temperature above 100℃ without external force. It doesn’t deform at 150°C. This high melting point is also very suitable for the furniture industry. For example, to produce a plastic chair injection molding machine, it is necessary to put PP raw materials into the injection molding machine for one-time injection molding. The heat generated during the production process can be used for the PP chair itself to disinfect and sterilize. This is another furniture that wooden furniture and rattan furniture can’t realize, especially when COVID-19 is spreading around the world. How important is a chair that has been sterilized by high temperature, and it is a safety guarantee for a family. This is one of the reasons why PP furniture has been selling hot in Australia and South America.

Polyethylene

Polyethylene material isn’t heat resistant, on the contrary, polypropylene is very resistant to cold. It has excellent low-temperature resistance (the lowest operating temperature can reach -100~-70°C). This material is very suitable for use in low-temperature environments.

4. Cost price

Compared with other materials, the price of plastic chairs has an absolute advantage. But the exact price depends on the specific material. The price of different materials is definitely different. Generally, the price of polypropylene (PP) is higher than polyethylene (PE).

Polypropylene

Plastic furniture is generally produced with PP raw materials. This new material has brighter colors, good light transmittance, exquisite appearance, high-grade and comfortable colors, and more expensive prices.

Polyethylene

Polyethylene is rarely used in the furniture industry. In addition to its inappropriate material properties, because polypropylene is very cheap. Especially many outdoor food stall furniture, blindly seeking cheap, the polyethylene chairs they choose are also very thin and fragile. This is why many people often see that food stall furniture always has broken corners and wear, which gives people the impression that plastic furniture isn’t strong. Moreover, many food stall furniture use waste plastics to reprocess them for secondary processing, the color is darker, the products are rough, and the toxicity is relatively high, the strength is also poor, but the price is cheap very much.

The above is the difference between PE furniture and PP furniture for food stalls summarized by MAKA for you. There is no good material and bad material, it can only be said that the performance is different so the purpose is also different, and finding the most suitable material is the best. So, PP food stall furniture can be durable than PE furniture.

MAKA FURNITURE has always been a high-quality polypropylene (PP) furniture supplier factory, supplying PP chairs and tables for many well-known international chain brands over the years, which not only depends on the design of our PP furniture but also comes from our strict control of the quality of the furniture. I believe MAKA will become your loyal partner, welcome to check and monitor our quality system https://www.bzmaka.com/qualified-manufacturing/

Fill out the contact form with your ideas today and find the right furniture sets for your room applications.