When buyers evaluate PP (polypropylene) tables for cafés, restaurants, terraces, or commercial outdoor spaces, appearance alone is never enough. Structural stability and load-bearing performance are the decisive factors that determine whether a table is suitable for real commercial use or only for light, residential applications.

Professional buyers often ask very direct questions:

This article explains how PP table structure directly affects stability, durability, and load capacity, using real structural logic rather than marketing claims.

Commercial PP tables generally adopt either one-piece injection molding or a KD (knock-down) structural system. In both cases, stability depends on how forces are distributed from the tabletop to the floor.

A well-engineered PP table typically consists of:

This structure allows vertical loads to be transferred efficiently while minimizing torsion and lateral movement.

Poorly designed tables fail not because of material, but because of weak load paths.

Wobbling usually occurs due to:

In a stable PP table design, the legs are evenly distributed in a star-shaped base, creating a wide footprint that resists side-to-side motion. This geometry significantly reduces rocking, even on uneven outdoor surfaces.

Additionally, reinforced connection points between the tabletop and the column prevent micro-movement that can worsen over time.

Result:

✔ Stable feel during use

✔ No lateral shake when leaned on

✔ No long-term deformation under normal commercial loads

One of the most common buyer concerns is:

“If weight is placed at the center of the table, will it sag or collapse?”

This is a valid question, especially for café and bar tables where customers may lean, place heavy items, or even briefly stand against the table.

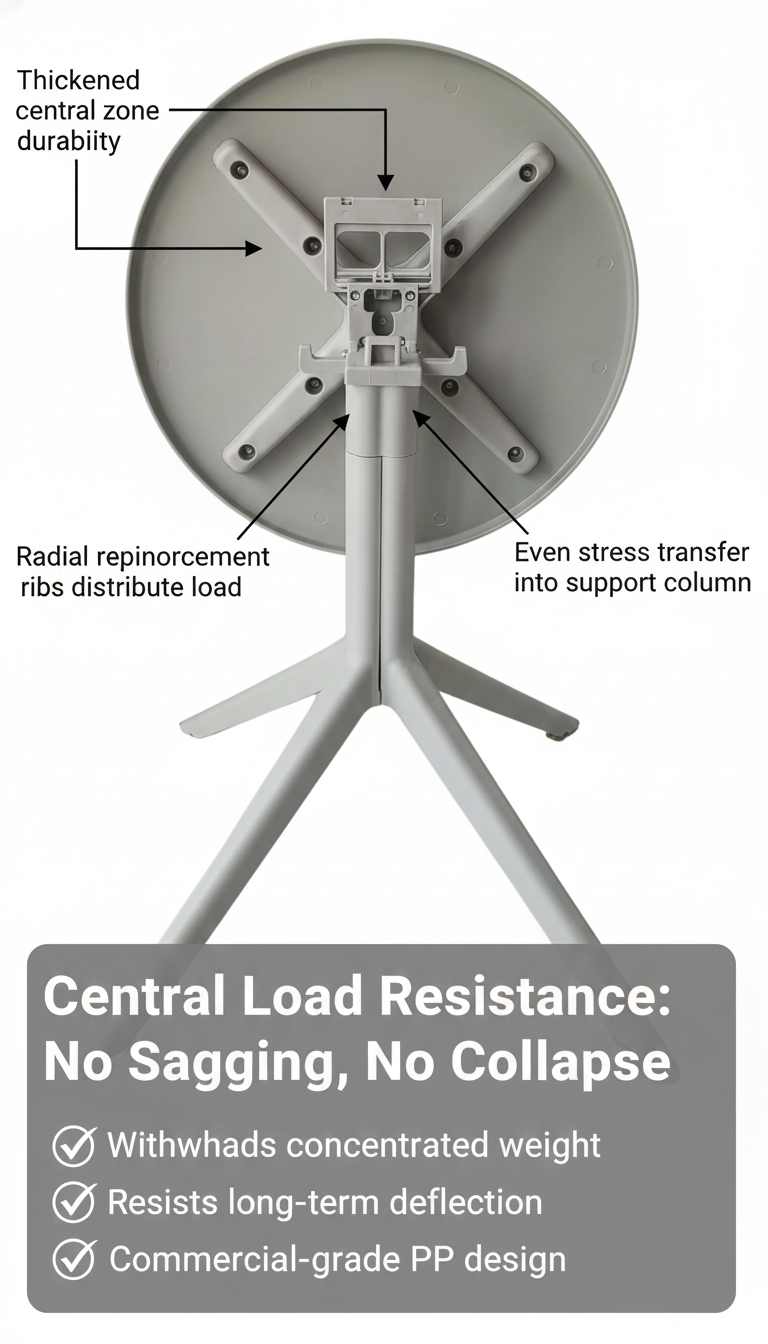

A commercial-grade PP tabletop addresses this through:

When properly designed, the tabletop does not rely on surface thickness alone. Instead, internal reinforcement distributes the load across the entire structure.

This ensures:

Professional buyers distinguish between static load and dynamic load:

A commercial PP table must withstand both.

Well-engineered PP tables are designed to handle:

This is achieved through:

Many failures occur not at the tabletop or legs, but at their connection.

A reliable PP table uses:

This design prevents:

For buyers, this means long-term stability, even in high-turnover hospitality settings.

A true commercial PP table is not tested for appearance—it is tested for real behavior under load:

Structural stability ensures:

This is why experienced buyers always evaluate structure first, aesthetics second.

When buyers ask, “Will the tabletop collapse?” or “Will the legs wobble?”, they are not being difficult—they are protecting their business.

A well-designed PP table answers these concerns through:

In commercial environments, structural stability is not a feature—it is the baseline standard.

Fill out the contact form with your ideas today and find the right furniture sets for your room applications.